Machining Center

Machining Center

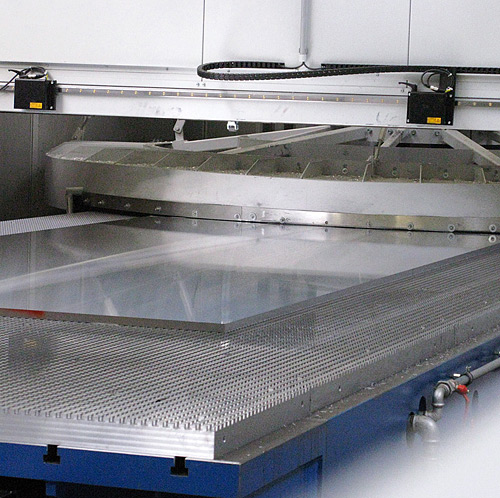

Behind the scenes at BIKAR. Simply gigantic. At our machining center, we machine in a different dimension. A giant cutting head 106.3 inches in diameter machines pre-sawn aluminum plates flat, ready for tooling.

Working flat out:

we make sure that surfaces stay flat

Step by step from block to plate

Sawing to size

This is our raw material:

Aluminum blocks with the following dimensions:

236.2 and 157.5 x 64.9 x 23.6 inches

236.2 and 157.5 x 86.6 x 23.6 inches

125.9 x 64.9 x 39.4 inches

Whether horizontal or vertical, we can saw almost any dimension.

Machining flat

The pre-sawn raw plates are machined flat to tolerances measured in tenths of a millimetre.

Applying film

These precision-cut plates are then covered on both sides with a protective film to ensure the surface stays absolutely flawless.

Pre-cutting

We use a state-of-the-art saw plant to cut everything to your precise requirements. From the size of a postage stamp to a telephone booth – whether cubes, plates, blanks, rings or parts from drawings. We have a wide range of options available.

FORMODAL® plates

FORMODAL® plates are aluminum alloys that have been developed specially for tool making, mold making and model making. They range from cast materials given special thermal treatments (FORMODAL® 023 and FORMODAL® 030 flat) to high-strength, rolled or forged plates (FORMODAL® 060 and FORMODAL® BM-400). BIKAR is the partner that you can rely on.